Medical staff members are being asked to make their surgical and N95 masks last for as long as possible. We are hearing nurses report that masks are being reused for periods of a week or longer, if they are lucky enough to have surgical masks at all!

A local hospital informed us that they are looking for ways to extend the useful life of the masks they have.

We quickly ruled out any 3D printed solution due to the large numbers of protective covers needed.

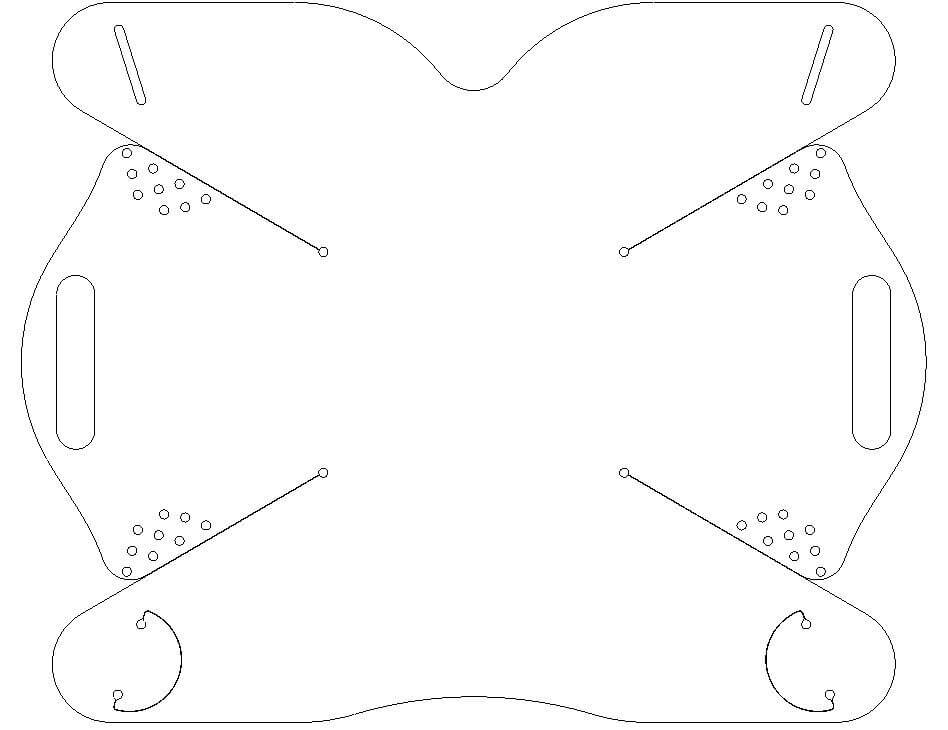

After a few quick iterations, here are two versions we are currently testing.

Both versions can be made from a sheet of 8.5 x 11″ flat sheet material. So far we’ve optimized designs for two materials, Cellulose Acetate (transparency sheets for overhead projectors), and construction-grade Tyvek material, available at Home Depot or Lowes.

Iteration 1: Cellulose Acetate Mask Cover

When used with the model of N95 Mask shown in the photos below, it fits well and provides excellent ventilation, while providing a physical barrier to protect against airborne contaminants that would otherwise settle on the mask fabric itself.

One downside is that the acetate material tears very easily when any stress crack forms. We are testing thin Delrin sheet plastic next to see if this can be a multi-use solution.

Iteration 2: Tyvek Mask Cover

The version below uses standard construction grade Tyvek from Dupont. Tyvek is extremely lightweight and water resistant, while providing tear resistance as well. This may be a good option for a single use solution.

Ongoing Efforts:

We have delivered several versions to a local hospital for evaluation. If they prove useful, we will make the design available for public use.

We immediately found that the masks we designed around are not the same size as the standard issue surgical masks used by this hospital. We are now updating the design to fit a wider variety of mask sizes. The critical dimension in this case is the position of the slot where the mask elastic bands feed through the cover.

We are actively looking for partners to provide die cutting services for these covers, in the event that they are approved for use.

Please feel free to offer feedback, we are open to any suggestions for improvement!

0 Comments