A few years ago, Zaic Design teamed up with Enterprise Color Solutions to deliver a turnkey automation system to one of our clients.

Here is a brief summary of that project.

Case Study:

- Problem:

- >20,000 measurement data points needed for a new research and development effort.

- Each measurement required a high degree of physical accuracy

- Due to the high number of measurements and precision required, worker fatigue was influencing measurement accuracy.

- Solution:

- Automate the measurement process using a collaborative robot arm.

- The Universal Robotics Collaborative Robot (UR5) – was selected.

- A Robotiq force/torque sensing module was added to help with picking up and stacking samples.

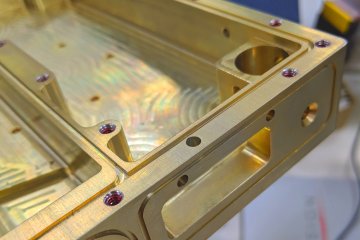

- We designed a series of custom fixtures, including a vacuum pickup plate, custom gimbal-mounts for client sensors, and custom stacking trays for the thin card-stock samples.

- For this solution, custom software needed to be developed as well. Enterprise Color Solutions wrote software to collect and log test data from the client sensors and trigger robotic movements coordinated with data collection.

- The code was flexible enough to be repurposed when the specific job was complete, and the robot was repurposed for another R&D effort.

- Automate the measurement process using a collaborative robot arm.

- Result:

- Complete success!! The testing rig has been running for 3+ years, often running unattended through the night. The client purchased a second robot to duplicate setup for added bandwidth. The same client has returned to us to help with re-purposing the setup for automated testing of new products.

We had a blast working on this project and we immediately recognized what a powerful and convenient tool collaborative robots can be for local businesses.

Collaborative robots such as those in the UR product line offer solutions never-before possible with conventional robotic arms. It is now safe and practical to install robots directly alongside skilled workers to handle repetitive menial tasks, while improving accuracy and efficiency.

Additionally, with new products such as the Flexx Reference, it has never been easier to deploy a single robot over multiple workstations, giving robot owners maximum flexibility and return on their investment.

At Zaic Design, we are a one-stop shop for mechanical design, custom fabrication, and software development to solve your automation challenges on-time and within budget.

Is there a repetitive task you are looking to automate?

2 Comments

| · February 27, 2023 at 7:47 pm

[…] of the most influential changes has been the integration of Robot technology. Robots can now communicate with, smart devices, machinery, and even each other, making them more […]

The Top Three Automation Trends Driven by the Changing Economy in 2023 | ZAICDESIGN NEW JERSEY · March 24, 2023 at 11:06 am

[…] and improve their own performance. At Zaic Design, we still believe in a human touch and personally tailor our automated solutions to meet the needs of the business leaders that contact us. However, we take full advantage of […]