Ordering 3D prints and CNC machined parts has become as easy as clicking a few buttons and uploading your STL files.

Why use a local prototyping shop like Zaic Design?

1.Confidentiality:

When you are designing components for a new product, you need to trust that your drawings will not be outsourced to a third party. If an online prototyping service is outsourcing to lower-cost manufacturing facilities outside of the US, it is impossible to guarantee confidentiality.

At Zaic Design, you can speak directly to the machinists who will be handling your parts. You can discuss any technical concerns face to face (social distanced of course!). We are happy to sign non-disclosure agreements for sensitive projects.

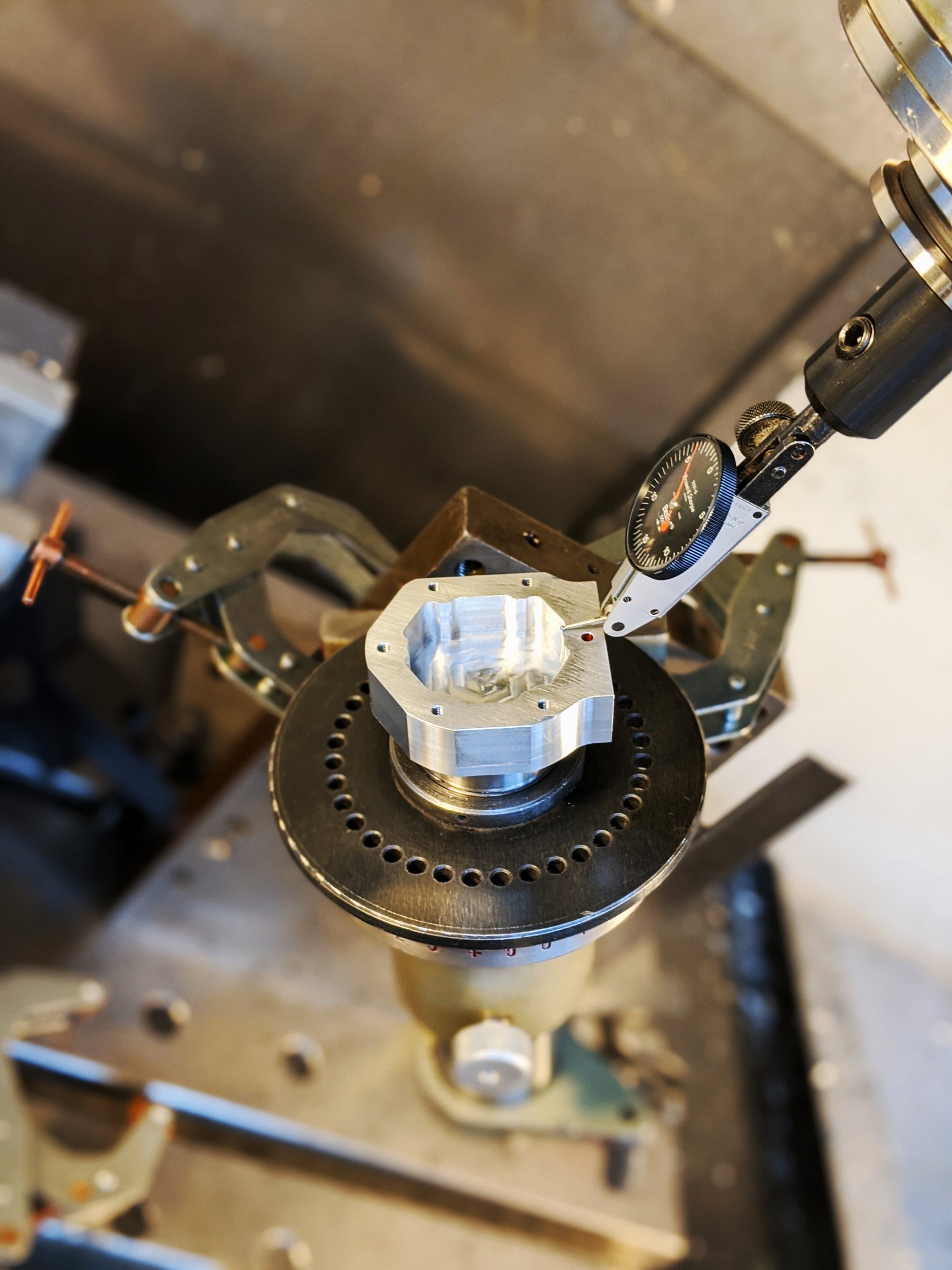

2. Close Tolerance Machining and Assembly:

In order to simplify the quoting process, online prototyping services usually offer nominal tolerances on all part features. While this is fine for basic prototypes, close-tolerance machining work requires more care and attention.

Our clients are welcomed to visit our shop and bring along parts that need to fit precisely into their assembly. We can easily machine or 3D print prototypes for exact fitting to a sample component, or match an existing product, as needed.

3. We Love Complex Parts!

Online prototyping services are great for low risk, low complexity prototyping.

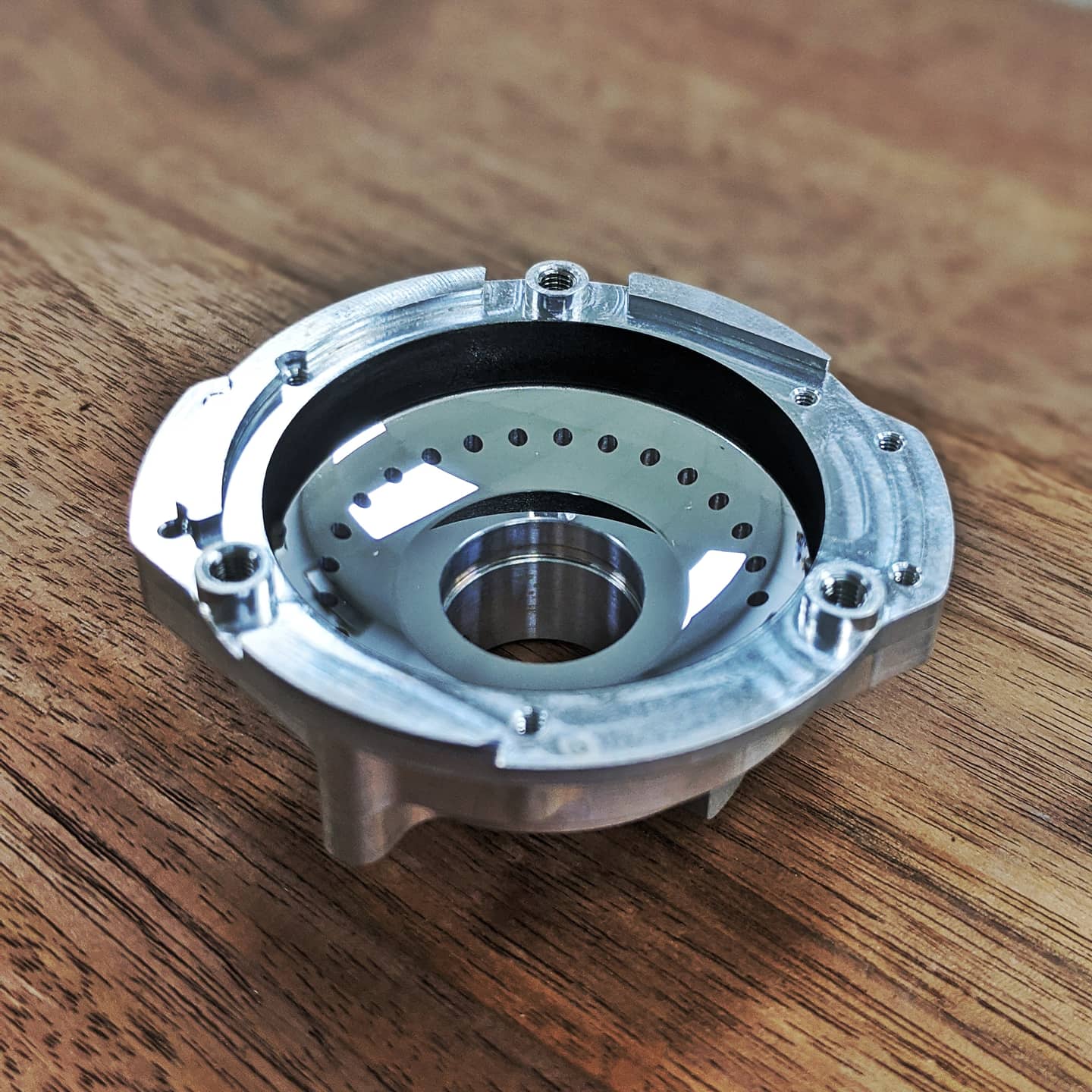

For high risk, high complexity machining projects, hands-on attention by an experienced machinist is a must. Much of our prototyping work involves machining custom opto-mechanical housings. In many cases, optical paths run through the part and need to meet precisely at pre-defined surfaces and datum planes. Highly complex machining projects are where we shine!

4. Specialty Coatings and Secondary Operations:

When tolerances are critical, even thin coating and plating operations need to be taken into account during the initial CNC machining process. We specialize in delivering parts with spot-painting and precision optical finishes, ensuring that all tolerances are within spec even after coating.

5. Precision 3D Printed Parts:

Do you have a high-precision design that will be injection molded in production? It is likely that 3D printing technology is not precise enough to adequately approximate the final molded part. We can often fine-tune a 3D print, using CNC machining and hand sanding, to bring your 3D print into the correct tolerance range for useful fit testing.

6. Presentation Prototyping:

Do you need to present your prototype in a client meeting or to get early customer feedback? We can deliver painted and polished, flawless prototypes that will get your project all the right attention. We carefully weight presentation prototypes and install working buttons for a satisfying touch and feel experience.

7. Speed and Convenience:

This is the number one reason our clients come to us for prototyping. Once we complete a prototype, small adjustments are possible within a few hours. Many times we have picked up a set of parts, made necessary revisions and returned them on the same day. This is a benefit that is only possible when using local prototyping services.

Our aim is to become partners with our clients, not just a faceless service. Give us a call for a free estimate!

0 Comments